Services

Since 1981 we have provided jewelry design, casting and finishing services nation-wide to qualified jewelery retailers. Send us a wax and we can cast, finish, and set stones for a ready-to-deliver product. And our custom jewelry, we can work with you from scratch beginning with an idea and a drawing. We offer a range of jewelry manufacturing services. We are Arkansas-based so your products are designed and made in the USA.

| Service | Price |

|---|---|

| Cast & clip (gold) † | $10 over metal per gram + $9 per piece |

| Cast & clip (silver) | $10 over metal per gram + $9 per piece |

| Cast & clip (platinum) | $25 over metal per gram + $9 per piece |

| High-polish hand finishing | $8 per gram ‡ |

| Special finishing: sand blast, brushed, etc. | per quote |

| Stone setting | Starting at $3 per stone ( see stone setting prices ).

If sending us stones to set, there is a $30 customer stone fee in most cases. |

| 3D CAD | $50-$400 (per quote) |

| 3D Scanning | most jewelry items/stones: $35. Other items: per quote |

| 3D printing (we cast or sample try-on)§ | Per part: $10 - per quote. Average ring $15. |

| Rubber mold (we/you keep) * | $40 / $100 |

| Hand milgrain | per quote |

| Hand engraving | $45 - per quote |

| Enameling | $10 - per quote |

| white rhodium plating small batch only | $35 per piece, $45 with masking per piece, quote when over 6 pieces |

| per Solder (assembly): simple-difficult | silver/gold: $8-$18, platinum: $14-$25 |

| Disassemble/tear-down Remove stones from mounting for new project |

Included in $30 customer stone fee, up to 20 stones. Then $10 per 20 stones |

| Rush (expedited) jobs | See our FAQ on deadline/turnaround and rush job fees |

‡ Not prorated

§ We no longer accept externally created CAD models. We do not 3D print for others to cast.

Prices are subject to change without notification

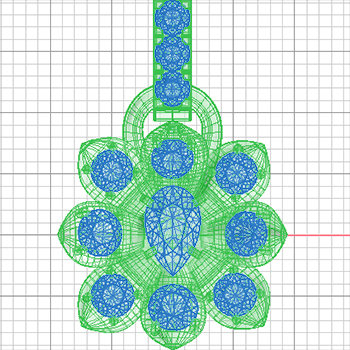

Custom Jewelry Design

Our award winning jewelry designers will work with you to bring your ideas to life. From a simple sketch or if you have pictures of an existing item and want something similar, send us your custom jewelry projects. Have your products designed and made in the USA by Specialty Casting. We can also help your design a full product line of fine custom jewelry.

We provide hand-carved wax models, 3D CAD design and high resolution 3D prototyping printing services.

See our How Custom Jewelry Manufacturing Works and some images of our work in our photo gallery

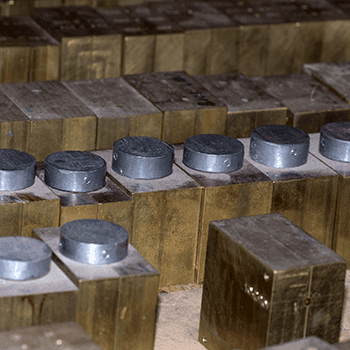

Rubber Molds

We can create rubber molds when required for jewelry production

- If a copyright exists on items submitted for duplication, you must own the rights.

- Rubber mold: $40 per mold setup fee. Non-refundable. Shrinkage factor with rubber molding and casting is 1-6%.

- A 25% deposit is required for the initial order.

- All molds created by Specialty Casting are kept in-house with the understanding that Specialty Casting does the production.

- If you don't place an order within 3 years of the mold creation date we reserve the right to destroy the mold.

Jewelry Casting

- We accept wax injection models, plastic injection models or rubber molds.

- We do not accept third-party CAD files or 3D printed materials for casting.

- We cast in:

- 10k yellow/rose/white gold

- 14k yellow/rose/white gold

- 18k yellow/rose/white gold

- sterling silver

- platinum

- Approved customers providing us a rubber mold or wax to cast, please print our Contract Casting Form and Terms & Agreement PDF, and include the form completed with the items.

Stone Setting

Our experienced setters are skilled at a variety of setting tasks.

- prong setting

- micro-prong setting

- channel setting

- full/semi bezel setting

- flush/gypsy setting

- pavé setting

- bar setting

- bead setting

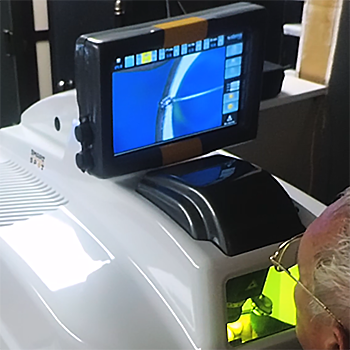

Laser Welding

With our state-of-the-art high-precision laser welder, we can:

- Weld precious jewelry metals

- Add metal and repair jewelry pieces: re-tip prongs, replace broken prongs

- Weld porosity or cracks using filler material

- Repair jewelry settings without removing stones

Finishing

Our polishing experts are skilled in lapping, buffing, application of rhodium and surface finishes. Every item that leaves our factory must pass our high standard of quality, and our finishing department ensures extra attention to detail.

- tumbled

- semi-finished

- sand blasted

- matte, satin, brushed

- bright high-polished

Engraving

- Laser marking/engraving

- hand engraving - Our hand engraver creates one-of-a-kind pieces - expertly crafting each piece with intricate details.

Additional Services

- Wholesale gemstones

- Casting runs of large quantity

- Rush services are available. See FAQ deadline questions for more info.

Specialty Casting is not liable for any copyrights or patents violated by manufacturing customer specific products. We reserve the right to reject submitted projects, artwork, and customer molds.