Mold Production

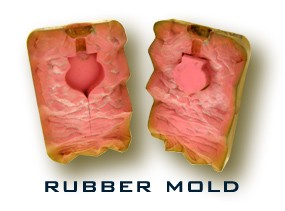

Large production of fine jewelry is commonly done using rubber molds or metal molds.

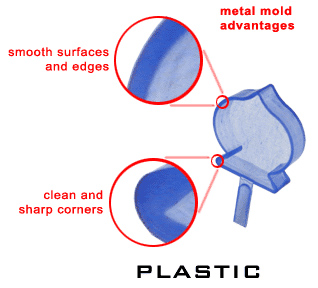

The Metal Mold Advantage

Metal molding is a state-of-the art technique for reproducing pieces with precision machining of metal with tolerances within .001 inch. Plastic injection metal molds give smooth surfaces, symmetrical pieces, small sprues, uniform weight, and a clean burnout in the casting process resulting in the best final product available.

Actual production molds:

The rubber mold above was provided from a customer for production purposes. It was decided to re-make the piece in a metal mold. The metal mold reduced the production time and greatly improved the overall quality of the product.

Rubber molds tend to wear and deform rather quickly with mass production. Metal molds outlast rubber molds hands down. The quality of the rubber mold wax finding below compared to the metal mold plastic finding is a prime example of the flaws with waxes and rubber molds.

Metal molds give a clean, consistent product with superior results and allow for finer detail in the designs.

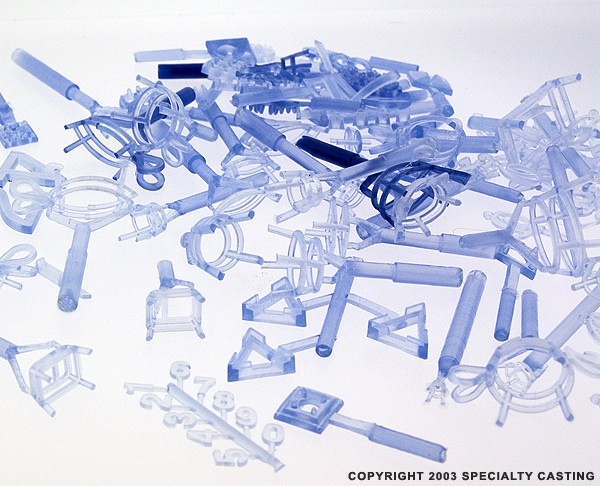

Plastic metal mold findings: pendants, heads, numbers, cluster tops, earrings, baguette settings, and more.

- Smooth surface

- Extremely durable

- Symmetrical pieces

- Small sprues

- Long shelf life

- Low cost

- Uniform weight

- Clean burnout